Projects: Bureau Plat Diplomatic Louis XV - Bronzes

Images relating to the implementation of the BRONZES of Bureau Plat

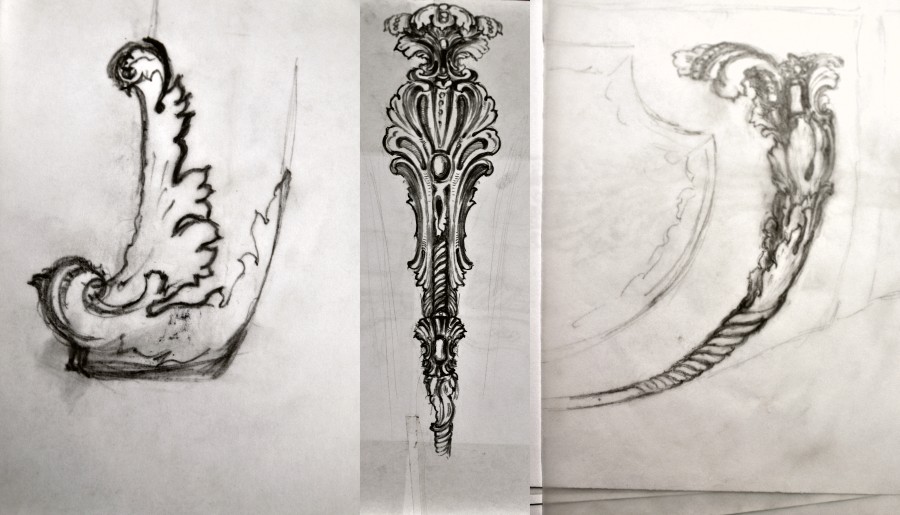

Fig. 1 - Sketches and preparatory drawings for gilt bronze decorations, which will adorn the bureau plat.

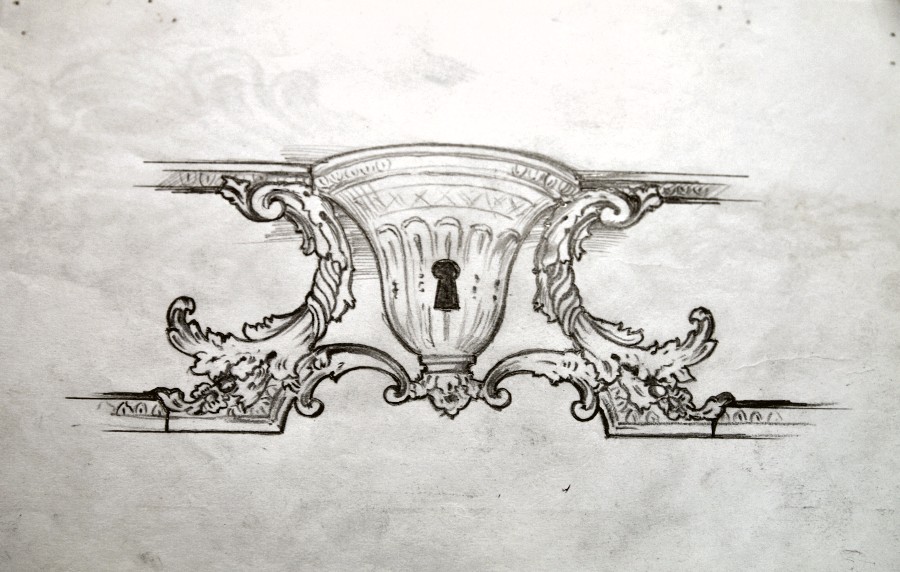

Fig. 2 - Sketches and preparatory drawings for gilt bronze decorations, which will adorn the bureau plat.

Fig. 3 - Previous designs must take shape before arriving at the final casting in bronze, becoming real sculptures made usually in the most suitable material to represent the technical characteristics.

As we can see from the photos, these materials can be wood, iron, wax, or a kind of resin that has the right hardness to be cut.

Fig. 4 - Previous designs must take shape before arriving at the final casting in bronze, becoming real sculptures made usually in the most suitable material to represent the technical characteristics.

As we can see from the photos, these materials can be wood, iron, wax, or a kind of resin that has the right hardness to be cut.

Fig. 5 - Sequence of handle models in various materials before arriving at the final casting in bronze.

Fig. 6 - Sequence of lock models in various materials before arriving at the final casting in bronze.

Fig. 7 - Sequence of handle models in various materials before arriving at the final casting in bronze.

Fig. 8 - Now it's time for bronze sculptor.

These templates are now transformed into definitive brass models, so they can be imitated without suffering alterations.

Each bronze decoration needs to be cleaned from all uncleanness with hand tools before being ready for the final process: gilding with gold leaf.

Fig. 9 - Another phase of the finishing of the bronzes.

Fig. 10 - Brushing the bronzes.

Fig. 11 - Piece of bronze just out from the melting (left) and the finished bronze (right).

Fig. 12 - Some bronzes of the Bureau Plat before the finishing.

Fig. 13 - A finished bronze and some finishing tools.

Fig. 14 - Some bronzes after the plating.

Fig. 15 - Some bronzes after the plating.

Fig. 16 - Detail of gilded bronze foot.

Fig. 17 - Detail of the floor molding at the invitation.

Fig. 18 - Detail of the key.

|